Toll refining is a service in which you contract the refining of platinum, palladium and rhodium for your scrap catalysts for a charge but the refined material remains under your ownership for final sale.

Customers who wish to manage their own refining of scrap catalytic converters can make use of our facilities, knowing that our results are highly dependable. As one of the leading recycling exponents in the East, and the only company in South East Asia with this technology, we are fully equipped to manage any sampling requirements for scrap catalyst recycling.

Nowhere is this more apparent than in the critical sampling stage that is used to determine the quantity and value of the three precious metals, platinum, palladium and rhodium, used, in varying amounts, in the manufacture of the catalytic converter. The need for accuracy and transparency is crucial – the company’s competitiveness, effectiveness and reputation for honesty are all at stake. Our sampling process is precise, measured and fully documented.

Our analysis of the precious metal content uses a top of the range XRF Spectrometer Analyzers renowned for their accuracy, reliability and speed. Our people are extremely experienced in working with this technology having received in-depth diagnostic training and we have supreme confidence in the accuracy of our findings.

Customers, or their appointed agents, are fully at liberty to witness our processes, and samples are made available for independent analysis, if desired.

Best practices and security are top priorities and our facilities equipped with the best talents and equipments available. Customers’ materials are monitored constantly, and are fully documented throughout the sampling process.

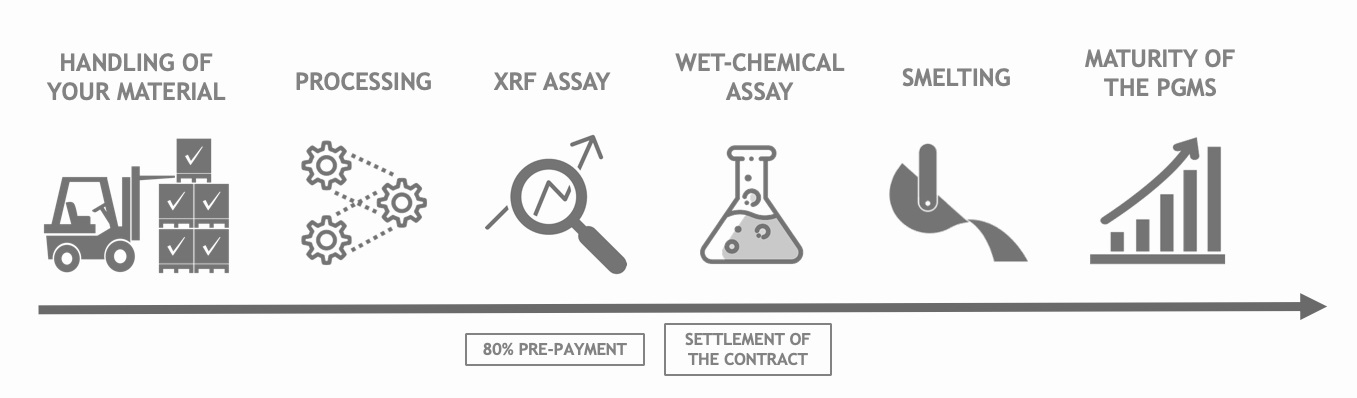

1.Processing and first sampling

When we receive the material, we remove the cat casing by a hydraulic shearing machine. We also deal directly with ceramics. The honeycomb substrates are broken and dropped into a collection container and are then further crushed into fine particles / powders with a ball mill machine.

2.Humidity test

Two separate drying processes are then carried out, the second of which takes 8-9 hours, and an accurate recording of moisture content is noted.

3.Second sampling

The powders are processed through fractional sampling machine where small quantities of powders are sampled out. Theses samples are divided into 4 sub-samples: one for the customer, one for internal testing, one for the independent laboratory and one for our “library”, to be available in the event of any discrepancies.

4.Assay

One sample is analyzed for platinum, palladium, and rhodium content at Ecotrade's premises and another can be sent to an independent laboratory.

5.Payment

We offer the following payment options:

- Advance payment of 80% of the value based on our XRF results, to be determined on the day after sampling.

- The remaining balance can be settled no later than 10 working days after prepayment under normal circumstances.

The final settlement will be based on the final test results (ICP) and after deduction of any advance payment and open charges.

6.Packing

The bulk catalysts are packaged and shipped to the smelter for the next process.

7.Smelting

The smelting process allows the recovery of platinum, palladium, and rhodium from bulk catalysts.

8.Refining

The final process of metals separation and refining of scrap catalysts into commodity grade form of platinum, palladium, and rhodium.

9.Delivery of precious metals

The commodity grade of PGM’s are delivered to Ecotrade's metal account or directly to the customers’ premises.

10.Trading of precious metals

Ecotrade actively trade platinum, palladium, and rhodium in US, Europe and Asia..

A) YOU DECAN ?

Material must be clean, dry, free of foreign debris and stored in big bags or metal drums.

If no metal (platinum, palladium, rhodium) has been hedged, the price can be fixed on the current market at the time your assay results are received.

B) WE DECAN ?

Ecotrade will de-can your converters AT NO CHARGE. On receipt, we will undertake a standard grading check and provide a report detailing weight of catalyst yield and anticipated precious metal returns. Provided the precious metal yield has not been sold in advance (hedged), the price can be fixed at the current market price prevailing at the time your assay results are determined.

BATCH SIZES

Minimum batch size - 500 kg

Maximum batch size - 5000 kg

You can send us as many batches as you wish; each batch should clearly identify your analysis requirements.

PAYMENT OPTIONS/ EARLY SETTLEMENT

We offer the following payment options:

- Advance payment of 80% of the value based on our XRF results to be determined on the day after sampling at our facility.

- We can offer an early settlement after final assays are available, which under normal circumstances shall be no later than 10 working days after sampling at our facility.

The final settlement will be based on the final assay results and after the deduction of any advance payment and open charges. Please be advised that any kind of advance or early payment will require the sale of the corresponding amounts of precious metals, which will be executed upon agreement with you.

Service available from 500 kgs

- XRF Spectrometer Analysis + ICP/Fire Assay

- Documented results and calculation

- Advance payment and possible hedging

- High level of accuracy (+99.5%)

- +20 years of experience in the industry

What is the minimum quantity for Toll Refining with Ecotrade? How long will it take for Ecotrade to transfer my payment? What is the payment method? How to know which company is offering me the best Toll Refining terms? Related articles

What machines are used in catalytic converter recycling? Five Self-Questions to Find Your Best Buyer Understanding Toll Refining Terms