Catalytic converter recycling is big business and plays a significant role in the effort to feed the constant demand for Platinum Group Metals (PGMs), all of which are in scarce supply. In its early days, this recycling was both logistically and technically complex, and whilst this, to an extent, remains the same today, improved efficiencies and technological advancements have helped the industry burgeon.

At the top of the recycling chain sits the refining operation, the removal of the PGM’s from the catalyst ceramic and metallic substrates. Smelters are the “real” refiners, melting metals to separate the alloy from its impurities, in order to recover the actual precious metals. The technology of the recycling process is rather complex and consists of many stages. It requires heavy investment, and, hence, has traditionally been carried out by large organizations, usually located in USA, Europe, Japan, that are capable of refining an extensive range of metals.

CATALYST Decanning and CERAMIC milling

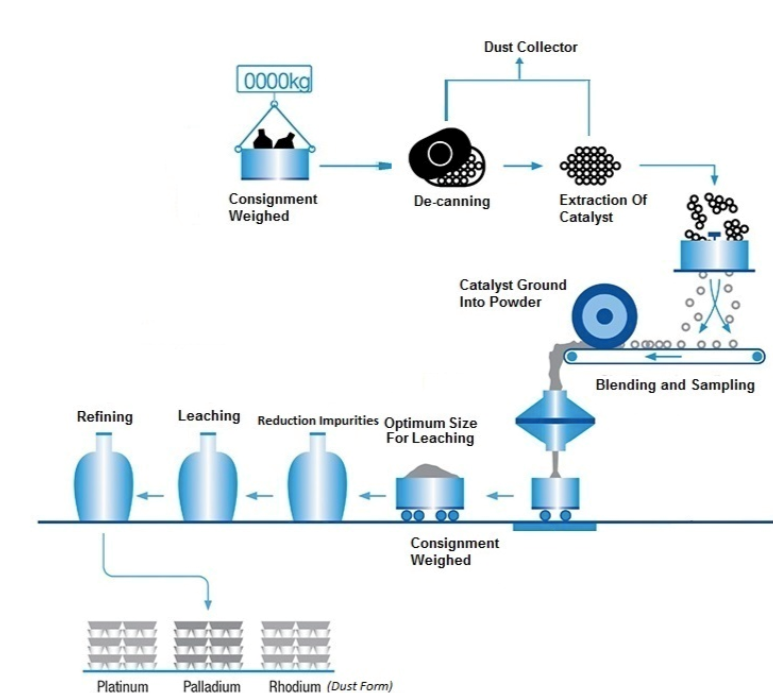

Once collected, catalytic converters are de-canned and the substrate crushed to a fine powder.

MATERIAL Sampling

Once processed, the batch will be sampled to determine its concentration of PGM.

Once done, material will be shipped to a smelter or a refiner.

Pyrometallurgical smelting

The preferred method for recovering PGM-bearing materials such as catalytic converters is a pyrometallurgical process, which delivers high recovery rates. This involves the thermal treatment of mineral and metallurgical ores to bring about physical and chemical transformations in the materials to enable the recovery of the precious metals. The nature of the operation usually has meant that large quantities of substrates - in excess of 1 ton - have been required to make up a “load”.

CHEMICAL Refining

After primary extraction, the precious metals are separated from base metals by chemical refining techniques including dissolution, solvent extraction, and selective precipitation. Alternatively, the ceramic substrate of some catalysts can be dissolved in acid leaving behind a concentrated residue of precious metals.

Whilst this is the basic process, and originally was carried out by major smelting companies with a background in handling metals that are in much higher demand (quantity-wise at least), technological advancements and growing demand have led to more forward-looking organizations entering the market.