Fire-Assay and ICP (Inductively Coupled Plasma) analysis is a widely accepted method in the Precious Metals industry.

It is a common practice for all Precious Metals collecting and refining companies to credit only 80% upon preliminary XRF results and credit full value upon ICP results.

These two combined methods are taking advantage of the Fire Assay’s full Precious Metal collection technique and ICPs simultaneous trace elemental analysis.

Fire Assay

Fire Assay is one of the oldest refining and analytical techniques for Precious Metals in the world.

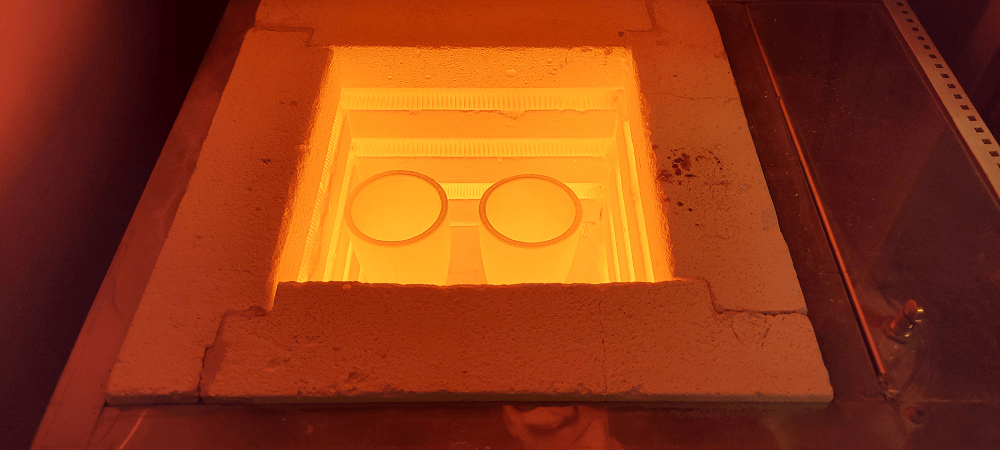

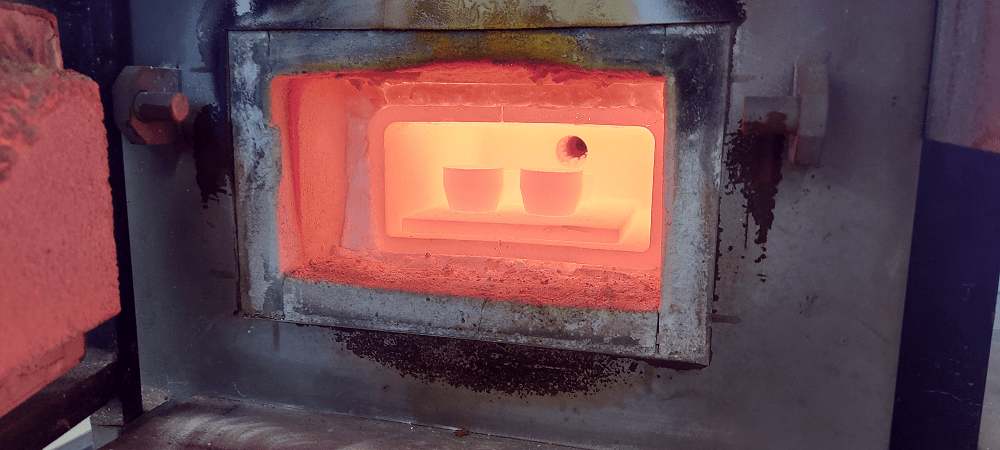

Even though modern instrumentation and machinery improved the time requirements, analysis performance, and reproducibility, the basic method remains the same.Powders are mixed with specific fluxes (according to the material's unique properties) together with a metallic collector (usually Pb) and then fused.During fusion, the fluxes and metal wash all metallics out of the powder and leave two separate parts of (A) a metallic “button” which contains all metals in the sample, and (B) a slag which contains all other remaining elements. The button is then dissolved in acid and analyzed by spectrometers.

ICP ASSAY (WET chemical assay)

ICP is an emission spectrometry method that identifies each element by its unique wavelength characteristic.

The acidic dissolved samples, like the buttons produced from the fire assay fusion, are charged in the high-temperature plasma (approx. 7000 K).

The emissions signals are received by a camera that collects and focuses the spectrum onto the Charge Injection Device (CID) detector.

The software then matches the received spectrum and compares the wavelength of each element producing a final result.

the Difference of ICP AND XRF Analysis

|

ICP |

XRF |

|---|---|

|

ICP is the method of choice when you want to measure multiple elements. The ICP-OES principle uses the fact that atoms and ions can absorb energy to move electrons from the ground state to an excited state. It is known and used for its ability to detect metals and several non-metals in liquid samples at very low concentrations. It can detect different isotopes of the same element, which makes it a versatile tool in Isotopic labeling. |

X-ray Spectrometers have gradually increased their effectiveness over the past decade, introducing new hardware and most importantly software analytics. However, the XRF results depend to a great extent on the sample preparation and especially on the sample particle size and homogeneity, as it analyzes only a small part of the sample’s surface. During sample preparation or pellet pressing, element segregation may occur resulting in usually small but sometimes big differences. At this stage, an XRF analysis can only be confirmed by the classical Fire-Assay/ICP method. |

Interested in analysis services?

At Ecotrade, we have a trained team of chemists for assaying your material. We use Fire Assay, Cupellation, Titration, XRF, and ICP Analysis. We have the ability to analyze apart from Scrap Catalytic Converters all Precious Metals containing material like Electronic Waste (Scrap PCBs), PGM Industrial and Petrochemical Catalysts, Karat Gold & Sterling Silver, Precious Metals Slags or Residues.

Why Fire assay + ICP analysis?

- Higher accuracy than XRF

- 2 different methods for more accuracy

- Most trusted combination in the industry

- Analyzing both major and traces elements